CTV:Ancient Technology

Archaeological Goals

• Identifying technological patterns in the various chronological periods of Timna’s smelting activity.

• Interpreting smelting technologies in their respective chronological timeframes as well as in a study of the longue-durée

• Understanding the technological development of copper smelting throughout Timna’s active productions phases

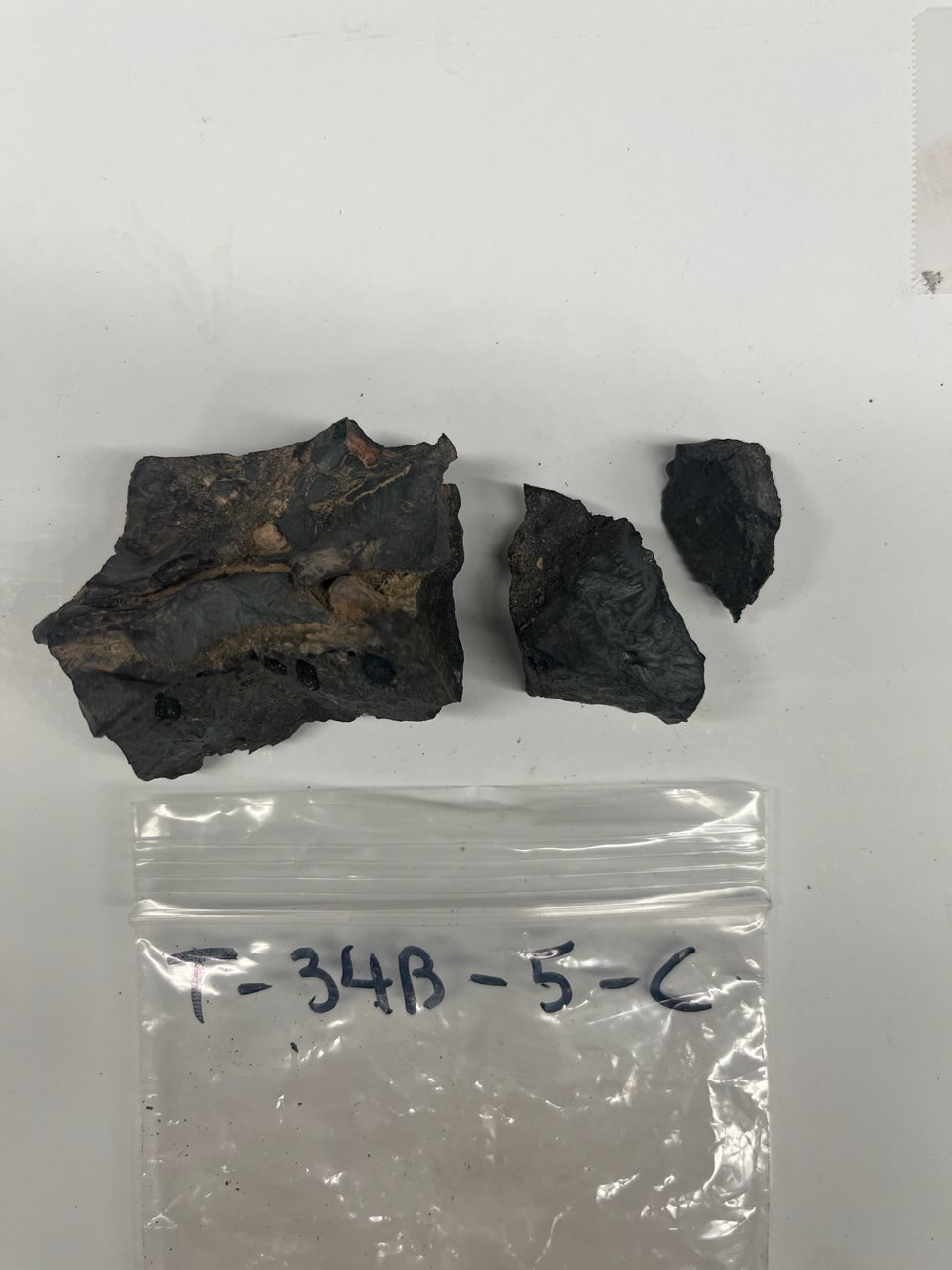

Slag samples from Site 34 - "Slaves' Hill"

Archaeological Question

• Can the glassy phase inside the copper slag present a proxy for varying ancient smelting technologies?

• Quantity of glass inside the slag

• Quality of glass inside the slag

• Location of glass inside the slag

Research Methods

• Identifying in-situ crystallographic and amorphous phases inside the slag

Main analytical method: SEM-EDS, image segmentation Sample state: Solid Cross-Section

• Mapping, Structure, Spatial Crystallographic and Elemental composition

• Quantifying crystallographic and amorphous phases in the slag Main analytical method: XRD, TGA (Thermo-Gravimetric-Analysis), Total-Content (Microwave Acid Digestion with ICP-OES) Sample State: Powder

• Quantitative Crystallographic and Elemental composition

Research Background

• Timna’s five main smelting activity periods:

o Early Bronze Age 3500-2200 BCE

o Late Bronze Age 1400-1100 BCE

o Early Iron Age 1100-950 BCE

o Iron Age II 950-800 BCE

o Early Islamic 650-1000 CE

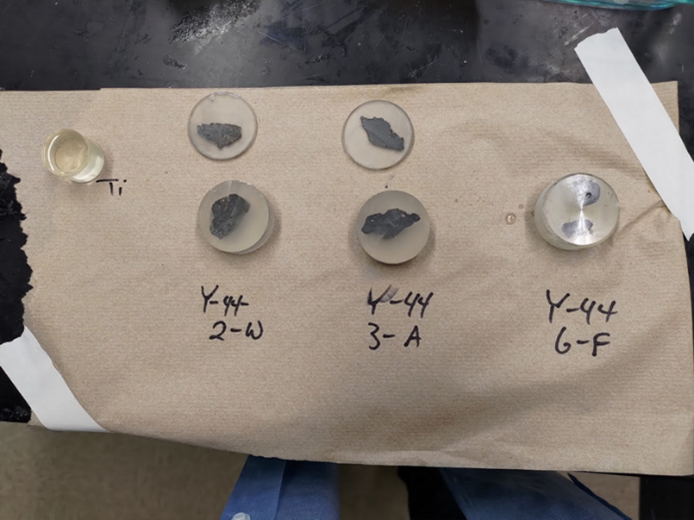

Research Material Collecting three copper slags from five different sites, corresponding to five different technological periods:

Total: 15 slag pieces

Early Bronze Age: Site: Yotvata 44 (Y-44) (ca. 2500 BCE)

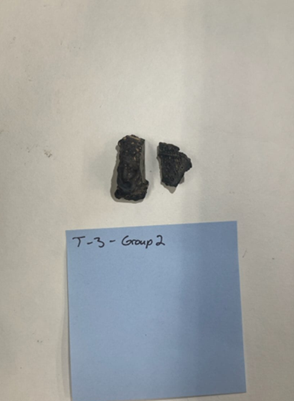

Late Bronze Age: Site: 3 (ca. 1150 BCE) Early Iron Age Site: 34(T) (ca. 1000 BCE)

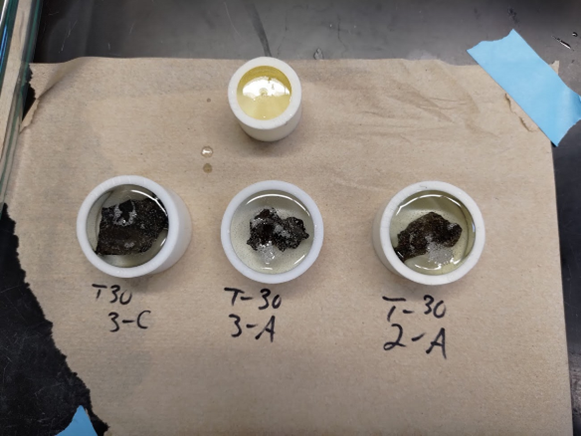

Iron Age II Site: 30 (ca. 900 BCE)

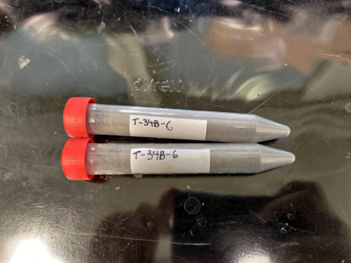

Early Islamic Period Site 34(B) (ca. 700-900 CE)

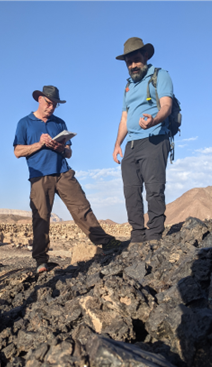

Prof. David Kosson and Prof. Erez Ben-Yosef collecting samples in Timna. November 2022

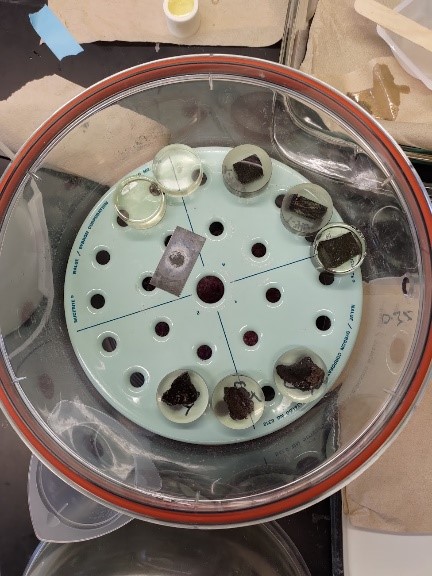

Sample Selection:

• Located three (large enough) intact slags from each site: Total: 15 Slag pieces

• Each intact slag was separated into two samples for two purposes: 1. Solid Cross-Sectioning: Epoxy mounting and polishing (for SEM) 2. Powder: Plate crushing and ball-milling (for XRD)

• Samples: Two from each slag 15 for sectioning 15 for powder Total: 30

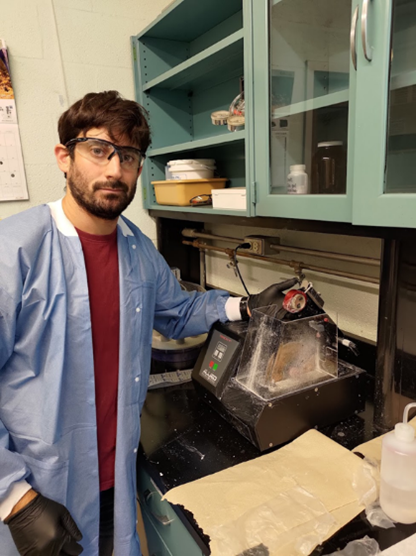

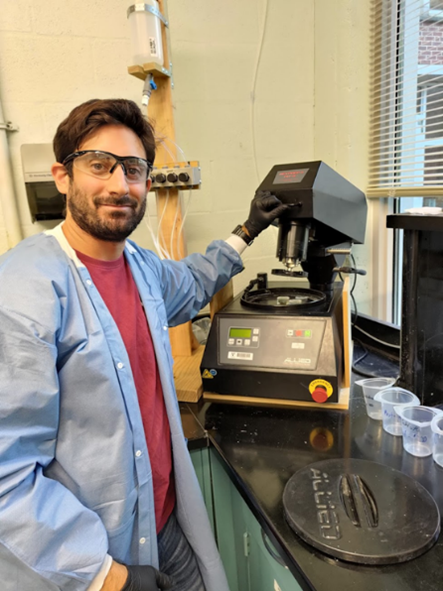

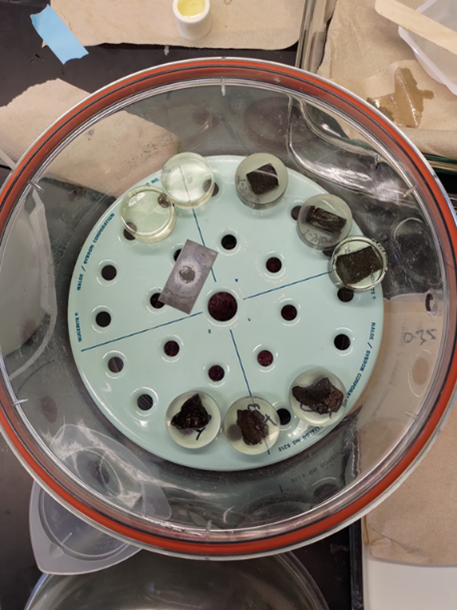

1. Solid Cross-Sectioning: Procedure

• Dry-sawing or chiseling the slag (shared with powder procedure)

• Extracting a small piece ca. 4x4 cm with an appropriate internal section

• Epoxy mounting and 18 hours hardening period

• Wet-sawing both ends for surface flatness

• Polishing procedure

• Polished Samples- Ready for SEM-EDS

2. Powder: Procedure

• Dry-sawing or chiseling the slag (shared with sectioning procedure)

• Extracting either several pieces or a small enough piece for the plate crusher

• Plate-crushing to rough grains

• Ball-milling to fine powder

Further research

Cross-Sectioning

• Initiate SEM-EDS process and assess the slag mineral morphology Powder

• Thermal gravimetric analysis (TGA) + Total Content analysis

• XRD for crystallographic analysis